A logistics audit (in our language: "Quick Check") - is, in simple terms, an assessment of the current state of logistics in a company. At this stage, we collect all the data that may be helpful in analysing the current state. This includes information on: product, employees (the state of human resources and their organisation), the current state of process automation (current status, capabilities and expansion needs) and productivity (where productivity is currently lowest and where the problem lies).

Purposes of the logistics audit

With a warehouse audit you will find out how efficiently your logistics is performing and whether you are using its full potential. Our auditors will make an in-depth diagnosis of the logistics situation in your company and identify the most important problems and opportunities in the following areas:

- conditions of current processes

- infrastructure (current state, expansion possibilities, automation)

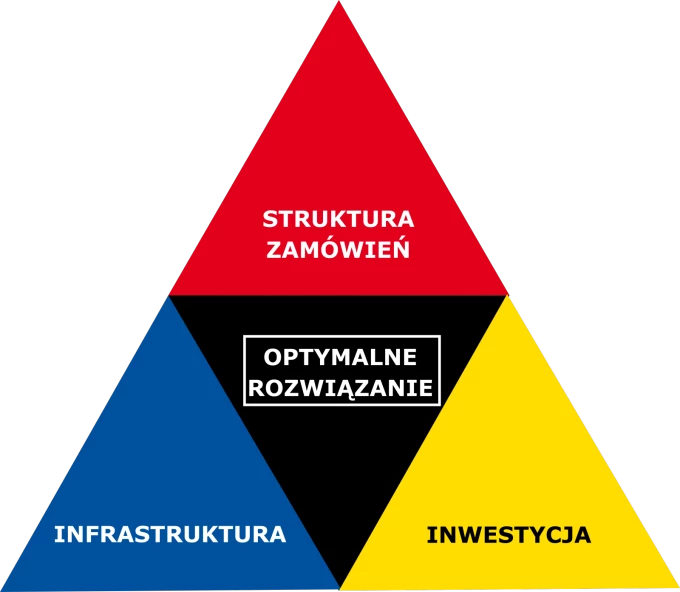

Following the above assessment, the auditor is able to identify the best, optimum solution, which will allow more efficient operation of the warehouse and, consequently, the entire company.

Evaluation of the current warehouse state

The Quick Check audit is primarily based on an assessment of the current state of the warehouse and processes. Here are some of the points required during the audit:

- Preliminary diagnosis of the company's logistics

- Identification of all elements in the logistics chain

- Selection of technical or organisational measures for the optimisation of processes (warehouse, production, distribution)

- Checking the company's susceptibility to automation

- Analysis of key parameters on which the decision to plan process automation depends (human resources, number of employees involved in the warehouse process, order line criteria)

- Finding hidden savings potential in the sense of increasing process efficiency

- Providing the basis for sound business decisions

Warehouse audit results

The result of the audit is a defined and justified path for the optimisation of the warehouse. Using process mapping or stream analysis (a complementary service to the audit results), we obtain a precise overview of the logistical processes in the warehouse and are able to identify areas for improvement.

The logistics audit is the starting point for extensive company logistics planning: a conceptual master plan and a detailed detail plan as preparation for the necessary investments.

Are you interested in a warehouse logistics audit? Get in touch with us. We will select the most favourable solutions for your company and provide you with a real ROI (return on logistics investment) period.