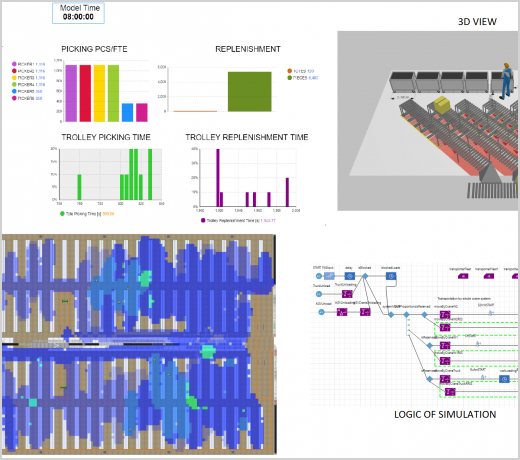

Process simulations become an interesting addition at the planning stage when we determine the performance of employees or the number of workstations needed with reference to their configuration as a variable. By changing the parameters of the variables, we obtain additional verification of assumptions based, for example, only on the experience of the project team or the customer itself. Simulations allow us to dynamically represent and analyse not only the varying flows of goods, but also the behaviour of employees and their interactions within the warehouse when the number of employees working at a station is a variable. They allow us to test the planned equipment and designed processes to suit the specifics of the presented project, before implementing changes in the actual warehouse environment. We are able to observe behaviour at any level of detail and compare different scenarios, allowing us to select the most effective variant in terms of equipment configuration and employees.

The processes that we can design in our simulations are primarily:

- Single/multiple-stage manual picking

- Receiving goods and packing orders.

- Manual sorting.

- Manual preparation of pallets for dispatch.

- Deployment of goods in the warehouse.

- Unloading/loading of vehicles.

- Special manual processes e.g. quality control or packaging.

- Employee behaviour during evacuation.

Thanks to process simulations, the client can compare and check the selected processes in terms of efficiency and functionality, even before making an investment decision or make a business analysis of existing warehouse processes.